Patching going terribly? 10 common problems and how to fix them – a guide for the beginner

A practical trouble-shooting guide to common problems you’ll face at your whole-cell patch clamp rig by Emily Winson-Bushby.

by Emily Winson-Bushby, PhD Student, Grubb Lab, Centre for Developmental Neurobiology

Introduction

Any patch-clamp electrophysiologist knows that, of the time you spend at your rig, the proportion dedicated not to collection of your precious data, but to fixing problems with your rig, will be much greater than you expect. Problems arise suddenly and unexpectedly, and if you’re unable to find a solution, your efforts to patch may be totally stymied.

Thus, in this article, I lay out a list of some of the most common issues you may face at the acute brain slice whole-cell patch clamp rig, and some of the most common solutions. You won’t find everything you need to make patching run smoothly here, but if you’re a beginner, you’ll certainly find some things here which will save you time when, unexpectedly, but inevitably, something goes wrong.

Pressure

Your pressure system is integral to your ability to patch – an insufficiently pressurised pipette will fail to blow away the debris between your pipette tip and the cell membrane you’re targeting, will make it impossible to form the critical dimple on the cell surface, and thus will make it extremely difficult, if not impossible, to form a seal.

Two main problems you may face:

1. Inability to hold positive pressure

If you find that when you reach your brain slice (or cultured cells) the pipette tip fails to blow at material in the vicinity, gently displacing it, despite your having pressurised the pipette at the start of your attempt, you may be facing a leakage somewhere in your pressure system.

To solve:

• Work through your pressure system (beginning from your mouthpiece and syringe, and ending at your pipette casing), tightening any joints or connection points. ]

• Check valves are positioned the right way, and, importantly, check the tiny rubber seals inside your pipette casing, that form a seal around the glass pipette. Sometimes these tiny rubber seals are clear, and very easy to lose! Make sure you know how many seals your pipette casing should normally have, and check they are all present, and all in good condition. Sometimes these seals can be leaky, and if you suspect this, you can replace them, so that they make a good seal between the glass of the pipette, and the pressurised chamber of the pipette casing.

2. Difficulty controlling your pressure to achieve the effects you want

Controlling your pressure precisely is key to your ability to form a good seals, and, critically, to break through the membrane. If you find that you are struggling to achieve the desired effect when you alter the pressure by mouth, or using a syringe, you may be facing a resistance issue in your tubing, or too large a dead volume.

To solve:

• Try replacing the tubing in your pressure system with shorter, wider diameter tubing. This might make it easier (effort-wise) for you to control the pressure inside the pipette by mouth.

• In addition, you may need to adjust the size of the mouthpiece you attach to your pressure tubing. A handy adjustable mouthpiece can be made using a 1ml Gilson pipette tip, cut with a razor blade, and fitted into the end of your tubing. By making transverse cuts at the tip and the base, you can control both the resistance at the end of your tubing, and the dead volume.

• Lastly, if you’re having issues with the syringes you’re using, trying different sizes of syringe may help.

Tubing and aCSF flow

To maintain your neurons, whether they are in a brain slice, or cultured, you’ll need a working flow system to circulate, oxygenate, and warm your artificial cerebrospinal fluid (aCSF). Cell survival in your preps is arguably the single biggest determinant of your success at patching, and so a problem with aCSF flow can bring you to a standstill, particularly if it threatens to leak sticky solutions all over the delicate equipment residing below your bath.

Common problems you may face:

1. aCSF fails to flow into your bath when you switch on the pump

Here, you may have an issue with the pump itself, the tubing you use, or the connecting pieces that join together pieces of tubing. To solve:

• A common culprit is blockage of any parts of your flow system which have a particularly narrow bore – ie, if you use a needle as a connecting piece anywhere, perhaps for the purposes of attaching a grounding wire, these can commonly become blocked by build-up of salts and solutes, or occasionally by a stray brain slice that has tragically escaped down your outflow tube. Replacing this needle can quickly solve the problem.

• Blockages (or leaks) can also occur in all other parts of your flow system. To locate the problem area, first look for blockages (areas which fluid appears not to move past) and leaks (areas which are dripping). If you can’t find any of these by eye, systematically disconnect segments of the tubing network, until you can generate successful flow through the path of tubing that remains. Once you have pinpointed the problem area, you can clear blockages with a syringe, or replace the component.

• Alternatively, you may have an issue with your pump. Check that you have switched on the flow in the correct direction, and at a high enough speed, and check that the tubing is fitted correctly into the right grooves or paths in the pump. Sometimes you may need to adjust the tightness by which the tubing is fitted to the pump – too low and you may not get flow, and too high you may have tubes which are stretched too tight to open. Old tubing may become stretched out and fall prey to the latter issue, in which case you may need to replace the piece of tubing in the pump.

2. Fluid pools in the bath, threatening to spill over

This typically results when the rate of outflow isn’t matching your rate of inflow, and to solve, you’ll need to restore the balance.

• First, simply reducing the flow rate on your pump may help – the output pump may be better able to cope with a lower flow rate.

• Moving the position of your outflow pipe lower in the bath may also help – typically the level of your outflow pipe is a strong determinant of the fluid level in your bath.

• If neither of these are working, check for a blockage in your outflow pipe, and outflow tubing! If the fluid level suddenly starts to rise, after remaining steady all day, this will be the most common culprit.

3. You cannot raise the level of liquid in your bath high enough, making it hard to raise your water-immersed objective high enough to fit your pipette underneath

To fix this problem, you’ll want to try the reverse of strategies for problem 2.

• Try increasing the flow rate on your pump, raising the level of your outflow pump, and if all fails, checking for a blockage somewhere in your inflow tubing.

4. Your bubble trap is filling up, leaking, and exploding

You may not have a bubble trap in your solution flow system, but if you do, it will likely look like sealed hard plastic tube into which aCSF drips from tubing at the top, and then flows down tubing at the bottom.

In order for a bubble trap to work, it needs a tight seal, so that the aCSF dripping in can raise the pressure in the trap, forcing aCSF to flow through the tubing at the base.

• When the seal on a bubble trap is compromised, solution dripping in will not raise the pressure in the trap, but instead simply fill it up. You can improve the seal by replacing any parts of your bubble trap which aren’t tight.

• When the seal on a bubble trap isn’t strong enough to withstand an elevated pressure, the bubble trap may explode once the pressure inside it begins to increase. Securing the seal by wrapping elastic bands around the structure may help.

Carbogen

To maintain your brain slices, a good supply of oxygen (and CO2), in the form of carbogen, is critical. You’ll want to be confident that your carbogen bubbler will work for you consistently, because even short periods of anoxia will harm your cells. Regular checks that your slices and aCSF are being bubbled sufficiently will serve you well.

If you notice your carbogen bubbler isn’t working, act quickly:

• First, make sure that the carbogen flow is switched to open at the source, with the valves in your tubing all set in the right position for the gas to follow the path you want it to. Turning up the flow rate at the carbogen source may help too, if your equipment has this control.

• If none of these quick solutions work, move your slices to a different bubbler, if other carbogen systems in your close vicinity are still working. The partial pressure of oxygen in your aCSF will not immediately drop to zero within the first 5 minutes of the bubbler stopping working, but you don’t want to leave it much longer and risk your preps becoming hypoxic.

• At this point, you may want to check your carbogen tubing for leaks. Areas you suspect of leaking can be submerged in water (if sensible), and bubbles emerging are a sure sign of a breach.

• If the gas tubing is all in order, and the carbogen tap fully open and set to high, but you still see no gas, you may be facing an empty carbogen tank. Replacing these requires special training, so you should ask the person responsible for the tanks if it’s possible that yours is empty.

• Lastly, sometimes carbogen bubblers get blocked up with salts and solutes. Rinsing your bubbler well in deionised water at the end of each day will help prevent this problem, but if washing your blocked bubbler doesn’t clear it, you may need to replace it.

Debris in your pipette

If you find that your pipettes frequently become blocked at the tip by debris, you will need to identify which steps you could improve upon in the process you take to prepare your pipette. Dust and debris can creep in at many stages of this process, and it will serve you well to protect against this. I’ve heard many a time that dust is the ultimate enemy of patch-clamp electrophysiologists, and for good reason!

Steps you’ll want to address:

Capillary tubes and pulling pipettes

• First and foremost, it is important to keep the capillary tubes you use to pull pipettes clean and dust-free. Typically, you will be storing them in the tube they arrived in, and it is very important that you replace the top of this tube after every use, because this will protect your stock fromdust particles in your environment.

• When you handle your capillary tube, avoid touching the centre of it (the part that will eventually become the pipette tips), to avoid transferring any materials from your skin. If possible, also try to avoid touching the open ends of the capillary tube, to avoid depositing any material in them too.

Pipette-holding box

• Between pulling your pipettes and mounting them on your rig, make sure you are storing them in a dust-free container. A plastic petri dish with a thick strip of blutac is a common choice, and make sure, again, to replace the lid of this immediately after every use.

Internal solution

• It is important that you make sure that the internal solution you use to fill your pipette has been filtered properly, to remove any tiny debris that it might contain. Check that you are using the correct filter for the purpose (ask your supervisor), and make sure that the filter itself is clean.

Typically, if you take good care of your filter, it will last a couple of days, but if you are seeing persistent ‘sticky’ particulates in your pipette tip, it may well be coming from bacterial growth on your filter, in which case you will need to replace it. To clean your filter, rinse it out well after use with deionised water (using a syringe to push the water through it), and then dry it by using the syringe to push air through it, forcing out any last droplets.

• A note on filtering - if you are filtering your internal into an Eppendorf, always make sure you are putting your filtrate into a new, clean tube, because the original tube will probably still contain particulates.

• Finally, if you are having very persistent issues with debris and blocked pipettes, double-check with your supervisor that your internal doesn’t contain anything it shouldn’t. You will likely be adding things to your internal, like biocytin or dyes, and it’s critical to make sure that these are in the right form – they certainly shouldn’t be in a form that might aggregate inside your pipette.

Lastly, make sure that you filter your internal after adding these materials, and not before.

Pipette-filler

• The next step of your process to address is the tip filler that you use to load the internal into your pipette. It is important to keep the tip of your pipette filler very clean – if possible, don’t allow it to touch anything but internal solution and the inside of your pipettes. Typically you will be storing this in an icebox, so make sure that you angle it well such that the part which enters the pipette is up in the air, and not touching the ice or box. In addition, be sure to regularly replace your filler – with homemade fillers, I typically replace mine daily.

Pipette holder

• Lastly, if all else fails, you’ll want to make sure your pipette holder is clean, and not depositing any material inside your pipettes as you load them. Carefully use an air duster to remove any debris, and make sure that you are cleaning and chlorinating your electrode regularly.

Vibrations and drift

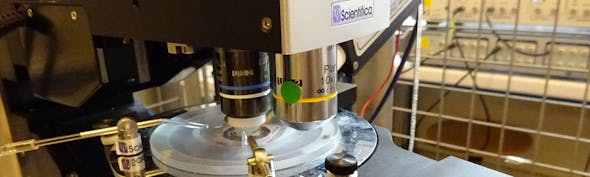

In order to maintain a solid seal on a cell, you’ll need to protect your patch preparation from vibrations as much as possible. Most patch rigs are placed atop an air-table, which uses air-cushions to isolate the table-top and protect it from vibrations which travel up the table legs.

If you notice your slice is looking particularly wobbly when you are looking at it under high magnification, this system may not be working sufficiently. You can get confirmation by stamping on the floor near your rig, or tapping the leg of your air table - a corresponding movement of your slice on the screen confirms this hypothesis.

To solve:

The first thing to check is whether your air table is working.

• The compressor which supplies the air table with pressurised air may be switched off, or may not be connected. Ask where it is, and check that it’s functioning well.

• Alternatively, you may need to adjust the air cushions of your air table, which you can see if you look at the underside of the tabletop. The corners of your table should be visibly lifted off the table legs by the air cushions contained in rubber balloons, but these balloons should not be so inflated that they become rigid, because rigid balloons will transmit vibrations like any other solid material. A good test for a well-functioning table is if a gentle push down on each corner of the tabletop, which should allow you to move the corner down, as if it were on top of a little bouncy castle. The tabletopshould then turning to its previous position when you release. Beware, also, for items trapped under the rim of your air table– these can interfere with the ability of the tabletop to bounce and up and down.

If your air table is working well, but your slice still vibrates when you stamp your foot, you may have a mechanical bridge somewhere, forming a connection between the patch set-up and the floor or surrounding furniture, bypassing the table legs altogether.

• Make sure your rig isn’t touching any surrounding units or furniture, and make sure any cables or tubing entering your rig are not taut, but as loose as possible, allowing them to absorb any vibrations they may be exposed to. The tubing you use for solution flow is particularly prone to transmitting vibrations, given the regular pumping of the fluid inside them, so do what you can to stabilise them.

Slow movements of slice or pipette

• If you can see your slice moving or drifting across your screen, you’ll want to check that your slice is well-secured by your slice-weight or ‘harp’, which keeps it in place despite the continual pumping in of solution.

• If you find your pipette tip is not vibrating but steadily drifting, you’ll first want to check that your pipette is held securely in the holder, with the parts keeping it there fastened tight. Next, you’ll want to make sure the pipette holder itself is

secured well in position, by tightening the screws you routinely use to move the pipette holder between the different positions you use for recordings and replacing pipettes.

• If the pipette is well-secured, pipette drift can be caused by uneven forces acting on your pipette holder, so try to reduce the number of cables and items pulling or pushing on your pipette holder. Drift can be a tricky issue – thus, for more detail, see also this article.

Pipettes

For a patching day to go well, you need to be able to easily obtain pipettes of a reliable size and tip resistance. Thus, if your pipette puller is pulling pipettes which don’t meet your requirements, you need to address the issue right away.

• The most common reason for a wrongly sized pipette tip is a change in temperature. If the temperature in the room has changed significantly (for example, if the weather has noticeably warmed up or chilled down), you may need to adjust the parameters of the pulling programme – ask your supervisor. If possible, ask them to show you how to adjust these parameters – knowing how to do this yourself will save your supervisor a lot of time.

• If the room temperature hasn’t changed much, your problem may be that you’ve pulled too many pipettes in a short period of time, without allowing the puller to cool down between each turn. Equally, if you’re pulling your first pipette of the day, the machine may not have warmed up yet, and the second pair you pull may well be better.

• Some pipette pullers have very delicate filaments, and another reason for poor pipettes may be that the filament has been damaged. In this situation, you’ll need to tell your supervisor, who may be able to replace it. This is a tricky job, so avoiding this situation is preferable for all – aka, always be very careful of the filament when loading capillary tubes into the puller.

Visualizing Cells

Here’s a frustrating problem – you can’t see your cells!

• Struggling to visualise healthy cells to target will make patching very difficult, so it’s worth taking time to learn how the microscope on your rig works. If you search your scope, you should be able to find the brand and model name, and this should allow you to find the user manual for it online (google search: name + model + “user manual”). Identify the positions of the major parts on your scope (objective lenses, condenser, field iris, light source, etc.) and the positions of major adjustment controls – (condenser focus, field iris control lever, light intensity control, etc.) and once you know where they are on your own scope, ask your supervisor to show you how they would like you to go about adjusting the optics of your microscope. They may advise you ‘Köhler’ your microscope if you are having trouble seeing cells, and should be able to show you how to do this. Otherwise they may advise you to leave it entirely alone, and ask them for help when you have issues. Either way, respect their answer!

Digital issues

Software and computer issues are outside the scope of this article, but a quick tip for lots of patch equipment is that: if it has stopped working normally, switching it off and on again may very well fix the issue. Ask your supervisor if your rig has any quirks about the orders in which you should switch on and off particular components, and abide by these. Always switch items off using the off switch on the unit itself, before switching off any extension cords or plug sockets, keeping the reverse order for switching items on.

• In addition, be aware that the software you use will typically have user manuals you can find online, if you search using the software’s exact name. You can find all sorts of useful information in these.

In conclusion

Happy problem-solving! I’ll leave you with three closing points.

1) First, don’t be afraid to use your common sense! Problem-solving at the patch rig is equal parts logic and experience.

Treat it as an experiment in itself – if you have a theory about what might be causing your problem, what else might you expect to be happening, and is it?

2) Be aware that patch clamp rigs exist in states of perpetual balance, and changing one variable will have knock-on effects on other parts of the system. For example, if you increase the flow rate on your pump system, say to try to improve the oxygen levels in your bath, you may have issues keeping your bath temperature high enough, because your solution is spending less time in the inline heater. In addition, the fluid level in the bath may begin to rise, because the output pump cannot cope with the increase in flow, and you may begin to see your brain slice move slightly in time with the pumping of your aCSF. The state of every component on a patch rig represents a compromise between variables, and keeping this in mind will help you greatly.

3) Lastly – every rig is different, with its own quirks, points of weakness, and workarounds. Taking the time to get to know your rig will help you in the long-run, and if you can talk to any of its previous tenants, they may be able to help you get acquainted with it quicker. Love your rig, and it will love you back!

)